April 16, 2018

MicroLink Devices is pleased to announce that it has been awarded the following Phase I and Phase II programs.

1) Navy SBIR Phase I Program: Floating Solar Arrays for Long-Endurance Sonobuoy Power Generation

The Navy has established the need for a long duration, maintenance-free power source to fit in a sonobuoy. Power sources are required to integrate into the Navy's existing buoy handling logistics and be ready for deployment and operation at any time without the need for peripheral charging equipment or human intervention. MicroLink Devices will develop a floating solar array that, when combined with rechargeable batteries, will be capable of continuously powering a sonobuoy for several years. The array will be composed of our highly-efficient, lightweight, flexible epitaxial lift-off (ELO) GaAs solar cells so that it can be rolled up inside the sonobuoy prior to deployment.

2) Navy STTR Phase II Program: Novel, High-Efficiency, Light-weight, Flexible Solar Cells as Electrical Power Generation Source

MicroLink Devices will integrate its high-efficiency, lightweight, and flexible solar sheets to the Puma UAS platform to significantly extend the flight endurance of the aircraft. The Navy has a growing fleet of small UAS vehicles that enable tactical ISR capabilities not possible before, and a need to extended mission lengths of these battery-powered platforms is apparent. MicroLink’s inverted metamorphic multi-junction (IMM) multi-junction ELO solar cell technology is the basis for manufacturing an advanced thin-film solar sheet technology that can produce enough power to sustain flight. MicroLink will apply volume production techniques to solar cell and module manufacture for scale up and cost reduction. Flexible solar cell array modules will be manufactured and integrated into the wing of a Puma UAS platform in a method that can be applied to other battery-powered UAS platforms. For the Puma, output power from the solar enhanced wing will be in excess of 130 W enabling 8 or more hours of flight.

3) NASA SBIR Phase II Program: Radiation Tolerant >35% Efficient Phosphide-Based Multi-Junction Solar Cells with Epitaxial Lift-Off

As the world leader in volume production of large-area ELO III-V IMM solar cells, MicroLink will develop phosphide-based ELO-IMM four-junction (4J) and five-junction (5J) solar cells that will enhance the performance and capabilities of solar photovoltaic arrays for a variety of future NASA missions. Relative to state-of-the-art incumbent (Al)GaInP/GaInAs/Ge wafer-based 3J space solar cells, the proposed 4J and 5J solar cells have superior radiation tolerance, higher beginning-of-life (BOL) and end-of-life (EOL) efficiencies (η), lower areal mass density, higher specific power, higher operating voltage, lower cost, and inherent flexibility.

About MicroLink Devices:

MicroLink Devices is an American owned company located in Niles, IL. Dr. Noren Pan cofounded MicroLink Devices in 2000. MicroLink has specialized in the growth of epitaxial structures that are used to make the high performance HBTs and power amplifiers that are essential to the high-speed communications industry. MicroLink is an ISO 9001 certified semiconductor manufacturer. Over the last eight years, MicroLink has been a prime federal contractor on projects to develop solar cells, detectors, lasers, and high-speed transistors. In recent years, MicroLink has ramped up the production of its ELO-based solar cells and sheets for use in mobile power generation applications.

Contact Information:

This email address is being protected from spambots. You need JavaScript enabled to view it.

October 24, 2017

MicroLink Devices has entered into an exclusive license agreement with the U.S. Department of Energy's (DOE) National Renewable Energy Laboratory (NREL) to commercialize inverted metamorphic multi-junction (IMM) solar cell technology. The IMM solar cell architecture enables the manufacture of solar cells with very high efficiency as well as light weight, which are ideal for powering satellites and solar aircraft.

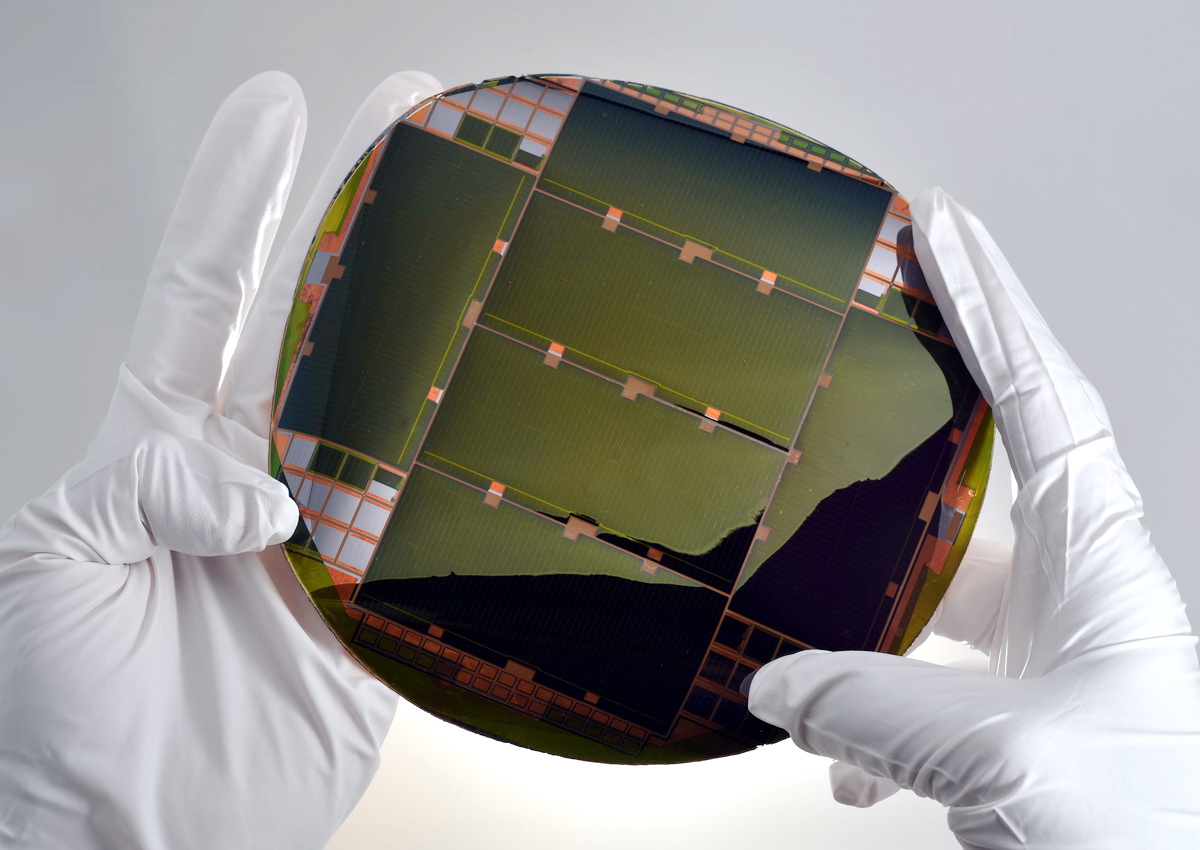

The world's most efficient solar cells are multi-junction, which means that they use multiple light-absorbing layers to convert different wavelength ranges of the solar spectrum into electricity. Multi-junction solar cells based on germanium substrates have historically been used exclusively in very high-performance satellite applications. The IMM design is an innovative approach to further improve solar cell efficiency by integrating an optimum combination of three or more compound semiconductor materials. IMM multi-junction solar cells are manufactured by depositing thin layers of semiconductor on a substrate such as gallium arsenide (GaAs). A metamorphic buffer layer enables the growth of junction materials with ideal bandgaps for energy conversion such as indium gallium arsenide (InGaAs) that are not lattice-matched to the GaAs substrate. MicroLink Devices has demonstrated an efficiency of 32.3% under 1-sun AM0 using an IMM design.

IMM solar cells are synergistic with MicroLink Devices' proprietary epitaxial lift-off (ELO) technology, which has been under development at MicroLink Devices for the past ten years. Using the ELO process, MicroLink is able to peel off thin layers of active solar cell material that were deposited on the GaAs substrate. Removing the substrate enables the fabrication of solar cells with exceptional light weight and specific powers greater than 3000 W/kg. The substrate can also be used multiple times to lower manufacturing costs. MicroLink's ELO technology was sponsored by numerous US agencies including NASA, DARPA, the Air Force Research Laboratory, the Office of Naval Research, NAVAIR, Army Research Office, Army REF, CERDEC, and the Department of Energy.

"We are excited to be manufacturing solar cells and arrays using NREL's IMM technology that have industry-leading performance as well as cost," said Dr. Noren Pan, President and CEO of MicroLink Devices. "We have been working for more than decade on the scale-up and manufacturing of this design, which enables us to provide very compelling solar solutions for powering high-altitude long-endurance (HALE) aircraft and space satellites."

MicroLink Devices has previously announced a production contract to provide ELO multi-junction solar sheets to Airbus Defence and Space for use on the Zephyr S HALE platform. The Zephyr is a new class of unmanned air vehicle that operates as a high-altitude pseudo-satellite (HAPS) enabling affordable, persistent, local satellite-like services. The aircraft runs exclusively on solar power, and the Zephyr aircraft is at the forefront of the HAPS arena, holding world records with regards to absolute endurance (more than 14 days) and altitude (more than 70,000 feet).

About MicroLink Devices:

MicroLink Devices is US-owned company located in Niles, IL. Dr. Noren Pan cofounded MicroLink Devices in 2000. MicroLink has specialized in the growth of epitaxial structures that are used to make the high-performance HBTs and power amplifiers that are essential to the high-speed communications industry. MicroLink is an ISO 9001 certified semiconductor manufacturer. Over the last ten years, MicroLink has been a prime federal contractor on programs to develop solar cells, detectors, lasers, and high-speed transistors. In recent years, MicroLink has ramped up the production of its ELO-based solar cells and sheets for use in mobile solar power, unmanned aerial vehicles (UAVs) and traditional satellite applications.

Contact Information:

MicroLink Devices, Inc.

Dr. Chris Youtsey, +1-847-588-3001

Chief Technology Officer

This email address is being protected from spambots. You need JavaScript enabled to view it.

September 20, 2017

MicroLink Devices is pleased to announce that it has been awarded a SBIR Phase I program by the US Army titled "Lightweight Flexible Solar Cells Performance Enhanced with Nanostructures".

In this effort, MicroLink will increase the integrated energy generated over an entire day by employing novel periodic optical nano patterns to optimize light propagation and absorption in epitaxial lift-off (ELO) GaAs solar cells. These nanostructures will enhance the absorption and trapping of light by minimizing surface reflectance and altering light propagation paths to increase optical absorption, particularly for longer wavelengths for which optical absorption coefficients are low. By increasing the optical path length within the cell, light trapping and photon recycling allows for thinner absorbing layers in the solar cell, thereby reducing the overall cost and weight of the cell. Flexible GaAs ELO solar cells employing optical nanostructures will dramatically outperform the existing II-VI based solar cells such as CIGS and CdTe, or a-Si:H.

September 1, 2017

MicroLink Devices is pleased to announce that it has been awarded the following NASA SBIR 2017 Phase I programs.

1) Title: Flexible High-Efficiency Solar Panels for SmallSats and CubeSats

MicroLink will develop and test, a new type of photovoltaic module that will be suitable for use in SmallSat and CubeSat platforms requiring maximum power in a highly stowable format. Utilizing MicroLink's high-efficiency, lightweight, and flexible epitaxial lift-off (ELO) solar cell process, an advanced flexible solar array suitable for space will be assembled that will demonstrate a pathway for producing significantly larger arrays capable of outputting powers in excess of 100 W. The typical areal weight of conventional Ge-based space cells with a 5 mil thick rigid coverglass exceeds 1,000 g/m2. MicroLink's proposed flexible photovoltaic module with ultra-thin ELO solar cells and flexible coverglass material will not only be flexible and comparable in efficiency to Ge-based cells but also have an areal mass of less than 400 g/m2. This represents greater than a 60% reduction in weight which is of particular importance for SmallSat and CubeSat applications.

The high-efficiency, flexible, and highly stowable solar panel technology to be developed in this Phase I program is ideally suited for building low-cost, high efficiency and lightweight power sources for potential NASA programs including solar electric propulsion and small satellites. Further, the technology developed under this program will lead to more efficient and more power dense space solar arrays, which will enable applications that are not possible today. The ELO process provides a unique technology platform that cannot be matched by any other technology at the present time.

2) Title: Radiation Tolerant 35% Efficient Phosphide-Based 4-Junction Solar Cell with Epitaxial Lift-Off

MicroLink Devices will develop a phosphide-based ELO-IMM four-junction (4J) solar cell that will enhance the performance and capabilities of solar photovoltaic arrays for a variety of future NASA missions. Relative to state-of-the-art incumbent (Al)GaInP/GaInAs/Ge 3J space solar cells, the proposed phosphide-based 4J solar cell has superior radiation tolerance, higher beginning-of-life (BOL) and end-of-life (EOL) efficiencies, lower areal mass density, higher specific power, and lower cost. The improved radiation tolerance is enabled by eliminating arsenide-based subcells in favor of only phosphide-based subcells. A reduction in the mass of the solar cell relative to incumbent technology is enabled by removal of the thick GaAs substrate. Cost savings compared to incumbent technology are enabled by the recovery and reuse of the substrate via the ELO process. The superior radiation tolerance can also relax the requirements for radiation shielding, enabling further reductions in array mass and stowed volume. The proposed 4J solar cell structure includes 2.10 eV AlGaInP, 1.70 eV GaInP, 1.35 eV InP, and 1.05 eV GaInPAs subcells. The AM0 1-Sun BOL efficiency of this structure is projected to be 35% at 300K. The remaining power fraction after exposure to 1 MeV electrons at a fluence level of 1E15 cm-3 is projected to be 92%.

3) Title: 3D Nano-Epitaxial Lateral Overgrowth (nano-ELOG) of Large Area, Highly Efficient, and Flexible Multijunction Solar Cells for Space Applications

By Epitaxial Lateral Overgrowth (ELOG) and Selective Area Growth (SAG) in nanometer scales, MicroLink Devices will develop the next generation of multijunction solar cells for space applications. This is the first attempt to use advanced surface nano-engineering technologies to control the formation, propagation and annihilation mechanism of extended defects including dislocations in multijunction solar cells. There is a significant gap between the theoretically calculated efficiency of multijunction solar cells and the experimental results. That efficiency gap increases with the addition of each junctions/subcells. Misfit dislocations created due to high lattice mismatch between subcells play a major role in hampering the efficiency and reliability of such devices. A successful implementation of nano-ELOG in solar cells will results in 3J solar cells with significantly reduced dislocation density, resulting in an improved Voc and Isc and conversation efficiencies of the cells. Therefore, MicroLink will utilize this method to grow devices with increased number of junctions to reach practical efficiencies close to 40% (6J) from the current 30% (in commercially available 3J cells) in AM0 and 1-sun conditions.

This technology will enable the manufacture of low-cost, high-efficiency, highly reliable and lightweight solar cell arrays for use in solar-powered spacecraft. The resulting lightweight flexible solar cell arrays with improved record-efficiencies will be an attractive replacement for the existing stiff, heavy carbon fiber panel-based arrays. For NASA, this will be an enabling technology for solar electric propulsion or any mission that requires electrical power. Inner Space and outer Space missions including NASA's Mars program can benefit from the developed technology.

About MicroLink Devices:

MicroLink Devices is an American owned company located in Niles, IL. Dr. Noren Pan cofounded MicroLink Devices in 2000. MicroLink has specialized in the growth of epitaxial structures that are used to make the high performance HBTs and power amplifiers that are essential to the high-speed communications industry. MicroLink is an ISO 9001 certified semiconductor manufacturer. Over the last eight years, MicroLink has been a prime federal contractor on projects to develop solar cells, detectors, lasers, and high-speed transistors. In recent years, MicroLink has ramped up the production of its ELO-based solar cells and sheets for use in mobile power generation applications.

Contact Information:

This email address is being protected from spambots. You need JavaScript enabled to view it.